brass → mjed

Brasses are alloys of copper and zinc (generally 5 % to 40 %). Brass has been known to man since prehistoric times, long before zinc itself was discovered. It was produced by melting copper together with calamine, a zinc ore. Its ductility reaches a maximum with about 30 % zinc and its tensile strength with 45 % although this property varies greatly with the mechanical and heat treatment of the alloy. Typical applications included gears, plumbing ware fittings, adapters, valves and screw machine products. The French horn is a valved brass wind instrument.

Brass may contain small amounts of other alloying elements, such as aluminum, lead, tin, or nickel. Lead can be added as an alloying element resulting in a brass that can be rapidly machined and produces minimal tool wear. Additions of aluminium, iron and manganese to brass improve strength, whilst silicon additions improve wear resistance. Brass containing tin (< 2 % ) is less liable to corrosion in seawater; it is sometimes called naval brass and is used in naval construction.

Brinell hardness → Brinellova tvrdoća

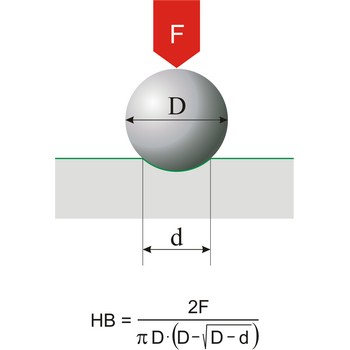

Brinell hardness is a scale for measuring the hardness of metals introduced around 1900 by Swedish metallurgist Johan Brinell (1849-1925). A small chromium steel ball is pressed into the surface of the metal by a load of known weight. The loading force is in the range of 300 N to 30 000 N. The ratio of the mass of the load in kilograms to the area of the depression formed in square millimetres is the Brinell Hardness Number.

Buchner flask → Buchnerova tikvica

Büchner flask (also known as a vacuum flask, filter flask, side-arm flask or Kitasato flask) is a thick-walled Erlenmeyer flask with a side arm to which a vacuum can be applied.

Buchner funnel → Buchnerov lijevak

Büchner funnel is one device used for pressure assisted filtration. Buchner funnel is a cylindrical porcelain filtering funnel (glass and plastic funnels are also available) that has a perforated plate on which the flat filter paper is placed. A vacuum in the flask underneath the filter allows atmospheric pressure on the sample to force the liquid through the filter paper. It is named after the German chemist Ernst Wilhelm Büchner (1850-1925) who designed this funnel in 1885.

Bunsen burner → Bunsenov plamenik

Bunsen burner is a standard source of heat in the laboratory. German chemist Roberts Bunsen (1811-1899) improved the burner's design, which had been invented by Faraday, to aid his endeavors in spectroscopy. The Bunsen burner has a vertical metal tube through which a fine jet of fuel gas is directed. Air is drawn in through airholes near the base of the tube and the mixture is ignited and burns at the tube’s upper opening. The flow of this air is controlled by an adjustable collar on the side of the metal tube. When the whole is closed a yellow safety flame is displayed. Where as when the whole is open it displays a power dull blue flame with a faint blue outer flame with a vibrant blue core used u for combustion and hearting. The flame can reach temperatures of 1 500 °C.

Bunsen’s cell → Bunsenov članak

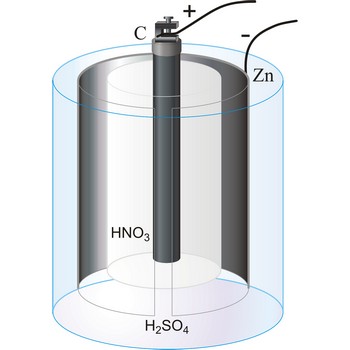

Bunsen’s cell is a primary cell devised by Robert W. Bunsen consisting of a zinc cathode immersed in dilute sulphuric acid and carbon anode immersed in concentrated nitric acid. The electrolytes are separated by a porous pot. The cell gives an e.m.f. of about 1.9 V.

burette → bireta

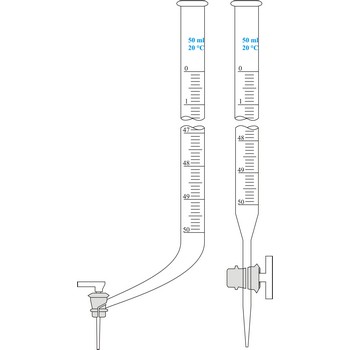

Burette is a graded glass pipe which on its lower side has a glass faucet by which it can drop a precise quantity of liquid. Inner diameter of a burette must be equal in its whole length, because the accuracy of volume measurement depends upon that. Burettes are primarily used in volumetric analysis for titration with standard solution reagent. Most often Schellbach’s burette is used, graded on 50 mL with division of scale on 0.1 mL. Every burette is calibrated on discharge. For serial determining automatic burettes are used.

Butler-Volmer equation → Butler-Volmerova jednadžba

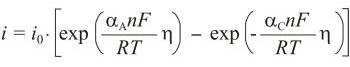

Butler-Volmer equation is an activation controlled reaction, the one for which the rate of reaction is controlled solely by the rate of the electrochemical charge transfer process, which is in turn an activation-controlled process. This gives rise to kinetics that are described by the Butler-Volmer equation:

where io is exchange current density, η is overpotential (η = E - Eo), n is number of electrons, αA is anodic transfer coefficient, and αC is cathodic transfer coefficient

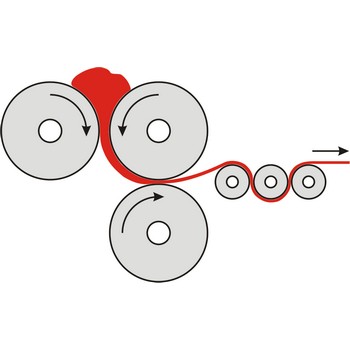

calendering → kalandriranje

Calendering is the process of forming materials to make a film/sheet by passing them through a series of hot rollers.

calomel electrode → kalomel elektroda

Calomel electrode is a type of half cell in which the electrode is mercury coated with calomel (Hg2Cl2) and the electrolyte is a solution of potassium chloride and saturated calomel. In the calomel half cell the overall reaction is

Table: Dependence of potential of calomel electrode upon temperature and concentration of KCl according to standard hydrogen electrode

| Potential vs. SHE / V | |||

|---|---|---|---|

| t / °C | 0.1 mol dm-3 | 3.5 mol dm-3 | sat. solution |

| 15 | 0.3362 | 0.254 | 0.2511 |

| 20 | 0.3359 | 0.252 | 0.2479 |

| 25 | 0.3356 | 0.250 | 0.2444 |

| 30 | 0.3351 | 0.248 | 0.2411 |

| 35 | 0.3344 | 0.246 | 0.2376 |

Citing this page:

Generalic, Eni. "Polietilen visoke gustoće." Croatian-English Chemistry Dictionary & Glossary. 29 June 2022. KTF-Split. {Date of access}. <https://glossary.periodni.com>.

Glossary

Periodic Table