chlorinity → klorinitet

Originally chlorinity (symbol Cl) was defined as the weight of chlorine in grams per kilogram of seawater after the bromides and iodides had been replaced by chlorides. To make the definition independent of atomic weights, chlorinity is now defined as 0.3285233 times the weight of silver equivalent to all the halides.

The Mohr-Knudsen titration method served oceanographers for more than 60 years to determine salinity from chlorinity. This modification of the Mohr method uses special volumetric glassware calibrated directly in chlorinity units. The Mohr method uses potassium chromate (K2CrO4) as an indicator in the titration of chloride ions chloride (plus a small amount of bromide and iodide) with a silver nitrate (AgNO3) standard solution.

The other halides present are similarly precipitated.

A problem in the Mohr titration was that silver nitrate is not well suited for a primary standard. The Danish physicist Martin Knudsen (1871-1949) suggested that a standard seawater (Eau de mer Normale or Copenhagen Normal Water) be created and distributed to oceanographic laboratories throughout the world. This water was then used to standardize the silver nitrate solutions. In this way all chlorinity determinations were referred to one and the same standard which gave great internal consistency.

The relationship between chlorinity Cl and salinity S as set forth in Knudsen's tables is

In 1962, however, a better expression for the relationship between total dissolved salts and chlorinity was found to be

Fahrenheit scale → Fahrenheitova skala

Fahrenheit scale is the temperature scale in which 212 degrees is the boiling point of water and 32 degrees is the freezing point of water. The scale was invented in 1714 by the German physicist G.D. Fahrenheit (1686-1736).

32 °F = 0 °C

212 °F = 100 °C

1 °F =(5/9) °C

T(°C) = (5/9)[T(°F) - 32]

T(°F) = (9/5)T(°C) + 32

heat of vaporisation → toplina isparavanja

Heat of vaporisation or enthalpy of vaporisation is the heat required to convert a substance from the liquid to the gaseous state with no temperature change (also called latent heat of vaporization).

latent heat → latentna toplina

Latent heat (L) is the quantity of heat absorbed or released when a substance changes its physical phase at constant temperature (e.g. from solid to liquid at the melting point or from liquid to gas at the boiling point).

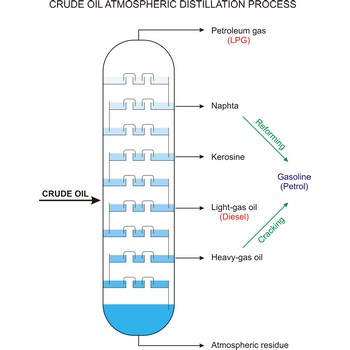

fractional distillation → frakcijska destilacija

Fractional distillation is a procedure in which liquids of close boiling points are separated. It is conducted in fraction or rectification columns in a way that vapour phase created by distillation is condensed and the condensate thus obtained is redistilled. The procedure is repeated several times. Vapour phase always contains more volatile component than the liquid phase, at top of the column vapour of clean volatile component gets out and at the bottom of the column liquid of nonvolatile component.

gasoline → motorni benzin

Gasoline is a complex mixture of volatile hydrocarbons that may have between 5 to 12 carbons. The major components are branched-chain paraffins, cycloparaffins, and aromatics. Gasoline is most often produced by the fractional distillation of crude oil as the fraction of hydrocarbons in petroleum boiling between 30 °C and 200 °C. The quality of a fuel is measured with its octane number. Octane number is the measure of the resistance of gasoline against detonation or preignition of the fuel in the engine. The higher the octane number, the more compression the fuel can withstand before detonating. The octane number is determined by comparing the characteristics of a gasoline to isooctane with good knocking properties (octane number of 100) and heptane with bad (octane number of 0).

Haber process → Haberov proces

Haber process is an industrial process for producing ammonia by reaction of nitrogen with hydrogen:

The reaction is reversible and exothermic, so that a high yield of ammonia is favoured by low temperature. However, the rate of reaction would be too slow for equilibrium to be reached at normal temperatures, so an optimum temperature of about 450 °C is used, with a catalyst of iron containing potassium aluminium oxide promoters. The higher the pressure the greater the yield, although there are technical difficulties in using very high pressures. A pressure of about 250 atmospheres is commonly employed. The removal of ammonia from the batch as soon as it is formed ensures that an equilibrium favouring product formation is maintained. The nitrogen is obtained from air. Formerly, the hydrogen was from water gas and the water-gas shift reaction (the Bosch process) but now the raw material (called synthesis gas) is obtained by steam reforming natural gas.

The process is of immense importance for the fixation of nitrogen for fertilisers and explosives. It was developed in 1908 by German chemist Fritz Haber (1868-1934) and was developed for industrial use by Carl Bosch (1874-1940), hence the alternative name Haber-Bosch process.

low-weight fractions → lake frakcije

Low-weight (petroleum) fractions have low boiling points and short carbohydrates chains.

petroleum ether → petroleter

Petroleum ether is the petroleum fraction consisting of C5 and C6 hydrocarbons and boiling in the range 35 °C to 60 °C; commonly used as a laboratory solvent.

Citing this page:

Generalic, Eni. "Normalno vrelište." Croatian-English Chemistry Dictionary & Glossary. 29 June 2022. KTF-Split. {Date of access}. <https://glossary.periodni.com>.

Glossary

Periodic Table